The Process of Mechanical Engineering

Mechanical engineering is the most versatile and diverse of all of the engineering fields. It combines materials science, physics, and mathematical principles to facilitate the design and manufacture of mechanical systems. They work well with their more art and design oriented counterparts in industrial design.

Not only is it the broadest engineering branch, but it is also one of the oldest. It touches almost every part of our lives, from complex technology to the human body! It has applications in aerospace, automation, energy, robotics, and even cybersecurity.

Mechanical engineering is unique in that it combines knowledge and analytics with creativity. This combination allows mechanical engineers to shape ideas into reality. In other words, they use problem-solving principles to bring a product from just an idea to the marketplace.

So, how can they do this?

To make things work, mechanical engineers must study the principles of motion, force, and energy. This will help them ensure that the product works efficiently and reliably. They will analyze the design to make sure that it is functional and durable, while also meeting the desired aesthetic.

They must also consider the environment that the product and its parts will encounter – they want to make sure that it will operate without failure!

As if that doesn’t seem hard enough, mechanical engineers also have to make this happen at a competitive cost – because otherwise what is the point of bringing the product to market?

Next time you buy something at the store and wonder how the idea for the product came to life, thank a mechanical engineer!

Why is it Important?

We already hinted at the importance of affecting, well, everything. Almost every service or product that we enjoy as part of modern life has been affected in some way by mechanical engineering.

Mechanical engineers are the key to many industries. The American Society of Mechanical Engineers (ASME) currently lists 36 divisions, including everything from aerospace and automotive to biotechnology and manufacturing.

Simply put, without it, we would not be able to solve the world’s problems or bring products to the market.

Mechanical engineers have created solutions in healthcare and transportation and have paved the way to space exploration and to progress the fight against climate change. They enable transformations on a personal scale, making technology like robotics and microgrids a reality. Likewise, the importance of mechanical engineering can be seen on large scales like advanced power systems that operate around the world.

Anything that needs to be built, designed, or has moving parts requires the expertise of mechanical engineers!

Mechanical Engineering in Product Development

You may be wondering, how does mechanical engineering fit into product design?

Well, without mechanical engineers, there would be no one to ensure designs could be produced. They build prototypes, test them, and ensure that the product is functional.

Mechanical engineers are the backbone of product development. They complete developmental design and put together presentations and reports. They can also benchmark your product against the competition to be sure it will be successful.

Sales and customer service also rely on mechanical engineers. Who else is going to explain how the product or process works, and help users troubleshoot it? Sales engineers are a great example. They are engineers who help create custom solutions or find applications for products with clients.

Mechanical Engineering Tools

Although mechanical engineers have been around for a long time, they don’t just rely on their knowledge to bring products to the market. Technology has shaped how they work, and they utilize unique tools to help them get the job done.

Computer-Aided Engineering

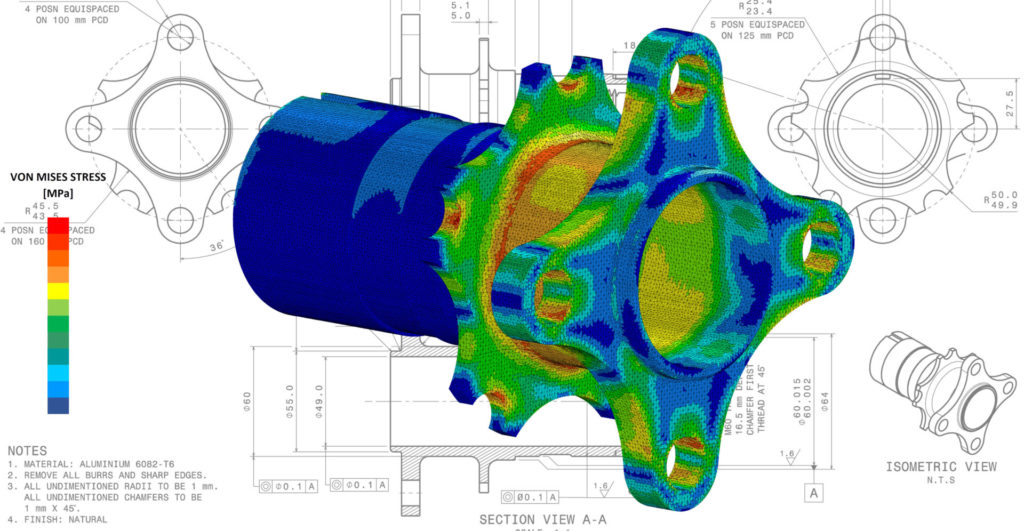

Computer-aided engineering, or CAE, refers to the use of computer software to test the performance of a product. This helps improve the design of a prototype and can help facilitate problem-solving. By using a computer, mechanical engineers can perform exhaustive tests and visualize product assembly without actually having to build it.

Think about the cost savings this provides – by using CAE, a mechanical engineer can cheaply iterate the design of a product to make sure that it meets performance, cost, and other constraints. They also allow them to solve problems that cannot be done manually, such as viscoelasticity or non-Newtonian flows.

Computer-Aided Design

CAD (computer-aided design) is perhaps one of the most well-known tools used by mechanical engineers. This software allows mechanical engineers to create precise drawings and technical illustrations.

It can create both two-dimensional and three-dimensional models. This allows them to design products like electronic circuit boards and other precise devices. Previously, the drawings would have been completed by hand, taking hours to do what we can now in minutes. CAD tools allow mechanical engineers to design faster and smarter.

CAD tools take this a step further and also facilitate the testing of a design. With this software, engineers can run simulations that calculate tolerance, measure stress levels, and simulate the flow of fluids within their designs. This lets them identify the strengths and weaknesses of the design without having to actually build a prototype.

Digital Calipers

There are all kinds of non-digital tools mechanical engineers use. Probably the most used one are calipers. A digital caliper is a simple and effective measuring tool. They are very accurate, down to thousandths typically, or more. This helps eliminate guesswork and interpretation required when taking measurements.

Flow Meters

The flow meter measures the linear, non-linear, volumetric and mass flow rates of gases and liquids. They include laser doppler anemometers and image velocimeters, which can identify magnetic fields or vibrations.

How much does Mechanical Engineering Cost?

Mechanical engineers solve problems with design, manufacturing, and other processes. They can work with anything from large systems like cars and machines, to small parts like switches and sensors. To do this they need a broad level of education and a wide variety of experience.

And this doesn’t come cheap!

The US Department of Labor estimates the top 10% of mechanical engineers earn over $130,000 per year. The mean salary lands just shy of $90,000.

Hiring Mechanical Engineers

We’ve established how important mechanical engineers are. Now you probably have the question, how do you hire them?

Effective mechanical engineers are highly skilled and experienced. This can be in a single specialty or as a generalist across a wide variety of competencies. They must understand design and manufacturing as a baseline. The best recognize the business processes surrounding a project.

A mechanical engineer must be well-versed in product development and design. They must be able to communicate effectively with other departments in an organization.

Without having all these skills, it may be difficult to identify a good mechanical engineer. You cannot afford (literally, they are expensive) to hire one that does not get the job done. It’s essential to validate their work history and expertise. Also, keep budget in mind. However, don’t skimp as it will cost you down the road.

How to Find the Best Mechanical Engineers

Finding the best mechanical engineers are essential to bringing your ideas to life. They provide key skills to any product development team. Finding them isn’t always the easiest thing, however.

Searching Google will likely overwhelm you with the amount of results. There are many engineers and engineering firms out there offering mechanical engineering.

DesignDirectory is a great place to start at. You want the right team, including mechanical engineers, to make it possible!

At Peterman Design Firm, our goal is to help you bring your products and brands from an idea to reality. We bring the best mechanical engineers to solve the problems unique to your business! Mechanical Engineers are a core part of our team.