Conscious product design is the next evolution in how I think we should approach the product design process. People are waking up and realizing that what we are doing isn’t working for the planet or us. I believe it’s time to begin shifting our basic processes for how we develop products. This starts with how we think about product design and then spans the entire lifecycle of the product. I would say that things are shifting, however we need it to shift faster. First, we’re going to briefly go over how most new products are developed now, concept to cash flow.

Standard Product Design

In any product design process, getting to your MVP is an important first step.

Ian Peterman, CEO Tweet

There are three ways to start a product. First, we can start with an idea and look for a hole in the market. Second, we can start with a market gap and create a product to fit the hole. Third, we can start with a real problem, create a solution, and the market will support that new product. Once we have that idea and the target market, we concept and develop the design. Sometimes this is to a high-level nearing perfection, but often we start with a MVP, minimum viable product.

We must make sure it looks right for the market, usable, sellable, and of course manufacturable. That process includes engineering, prototyping, testing, material selection, and many other finer points of product development. The focus is completely on the production, use, and aesthetics when new. Packaging is a key component to new products as is cost. Once we have a product that meets these requirements, we then create the marketing plan. From there, we launch the product into the market.

Missing Component

Lifecycle planning and management of products is skipped on most products developed today.

Ian Peterman, CEO Tweet

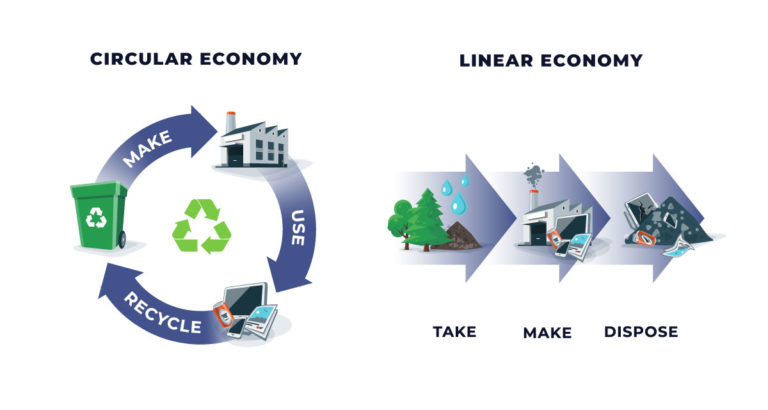

For the lifecycle management of most products the driving factor is often regulatory requirements only. Companies often skip looking deeper into the ecological or social impacts of a product and supply chain.

This is typically because of the additional cost this step takes. If there aren’t regulations, then money and focus are put toward increasing margins, decreasing product cost through production volume. The same goes for environmental impact. This is especially true for large supply chains where the company designing and producing the product doesn’t have full supply chain control. Supply chains are typically built based on price and end product quality.

Where does this leave the product? Likely up to the user as to whether something is recycled or tossed. Most people aren’t material scientists or recycling experts. So, the user is highly unlikely to know how to properly dispose of a product. There isn’t a buyback program, way to return it, etc.

Conscious Product Design

In any product design process, getting to your MVP is an important first step.

Ian Peterman, CEO Tweet

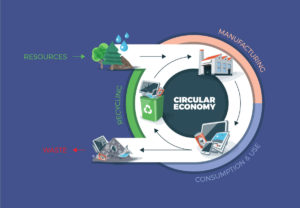

Now, let’s look at what conscious product design would look like. We’ve internalized and developed into our own proprietary process, the Peterman Method™. The process would look something like this.

We start with defining the why behind the product. What are all the goals of the product, from user to the CEO of the company, to the suppliers who will be involved. Once this is defined, it allows us to go through the process of defining a product that meets those goals. We look at every product and its impact across the board and ask a key question. Does this product improve the human condition? It’s a loaded question, because we look at direct impact to people, does it improve the lives of its users? We also ask, does it improve the environment of the world, is the environment impacted negatively by this product?

This is done with some products now, but not all. We take it another step further and we don’t just look at the “usable life” of the product. We look at the entire lifecycle. As a part of our road mapping and feasibility study, we look at the lifecycle of the product. What will happen to it at end of life? Can the product be recycled, repurposed, or composted? This isn’t just about the product though; packaging is a huge waste point and we want to look at it as well.

Product Impact

Moving to a circular economy will make every product better.

Ian Peterman, CEO Tweet

Conscious product design separates itself by focusing on the full impact up front and not just regulation focused. This process also removes the option for paying fines for not following regulations as a cheap way around being ecologically sound. This includes looking at the entire supply chain.

People are becoming more aware, especially with the food industry. This has given rise to things like fair trade, sustainably grown, and more. The days of ignoring the far reaches of your supply chain are gone.

Large companies can still bear the financial cost of ignoring it, for now. However, it can be a company killing mistake for startups. Brand damage for a bad supply chain that is unethical or damaging the eco-system is tallying up quickly. Green washing is only a band aid on an artery wound.

As a part of our initial phases, we scope out what it will take to ensure a clean supply chain. This means finding companies who can provide the needed services but maintain the same ethics and goals as you. Conscious product design is as much about ethics, eco-friendly, and socially responsible components as it is about integrity. Ensuring the integrity of the goals and missions of the product owner ensures that the product will be what it should be.

Design and Engineering

Design and engineering is the cornerstone of all design processes, including conscious design.

Ian Peterman, CEO Tweet

The design and engineering phases are pretty much the same as what we’ve been doing, however the key difference is the goals that have been set. The road map guides design and engineering to produce a product that meets the goals and mission of the company. We can design and engineer products that improve the human condition and make the world a better place. It just takes defining what success looks like for staying aligned with the mission.

Conscious Lifecycle

The more we shift toward recycling and reusing, the better our economy.

Ian Peterman, CEO Tweet

A few things that are added into the process of developing the product are that we now develop the end-of-life structure. There is a wide range of options here. Buy-back programs, recycling programs, and repurposing instructions on the product or packaging.

We can also just design it to completely biodegrade when no longer needed. The structure and processes must be in place for these things to happen. While it would be outlined in the early phases of the project, especially to determine feasibility and costs, its development and implementation must happen before product launch. Of course, this can cost more financially sometimes, which is why many companies ignore these steps still. However, a company who does this will be able to see financial gains from this as well.

User Focus

The true user of the product should always be in focus when designing a product.

Ian Peterman, CEO Tweet

Because we look at the end user and really understand their why and what their needs are, we can create products that better fit them. By being clear in the company goals, we can attract likeminded customers who will then use the product. When everything in alignment, whatever lifecycle management process is developed will ensure those customers stay loyal. Building loyalty through this type of design process can create customers for years, quite possibly generations. By tapping into the deeper side of humans and addressing their social, environmental, and “normal” problems you can offer a better solution. With that solution, you get a product with a greater emotional connection and a brand with stronger brand loyalty.

All of this comes from using a conscious product design process. Looking at the cost only and not paying attention to all the benefits, both financial and otherwise, is a huge mistake. The world at large is interested in products that improve more than one area of their life. They want to feel good about buying, using, and throwing away or recycling the products they buy. That’s why we developed the Peterman Method™, our approach to conscious product design and development. We want to ensure the longevity of our species, this planet, and improve the human condition with every product.

Your Next Steps

Related Conscious Design BLOG Posts

3 Important Things to Consider When You Hire a Designer

Working with different clients, I learned that there are many things that I find important. One of these important things is how to make it easier when you hire a designer. I found out that these three things are crucial if you want to hire the best designer for your project.

3 Things You Need Before Hiring a Designer

I’ve been working with clients for over a decade, and I’ve found that there are three things I’m always asking for. Every Industrial Designer would love…

Differences between Concept and Design

What is the difference between a concept and a design? Well, a few things it turns out. We explain the differences in this blog post.